ABOUT US

History Of LRA/RSL

LRA is a small R&D business founded in 1983 in Newport Beach, CA by Dr. Louis Raymond. The vision of LRA is to leverage military technologies, by minimal modification, to meet commercial and space requirements and effectively transfer into the product marketplace, with a special focus hydrogen embrittlement (HE) and stress corrosion cracking (SCC). In support of failure analysis, LRA has developed rapid, inexpensive testing techniques that use miniature specimens for evaluating SCC and HE. The focus of LRA is developing methods for use in failure analysis, where small specimens and accelerated methods are essential. Normal test methods for evaluating material for KIscc required more material than was available for most failure analyses and required way too much time to produce results within the time limits demanded of a failure analysis.

These unique, accelerated test methods have a long history of development. They were found to be successful for HY-130 weld metal studies for NAVSEA under a previous SBIR "Accelerated Stress Corrosion Cracking Screening Test Method for HY-130 Steel", (PHASE I & Phase II - Final Reports: SBIR Topic N88-84: Naval Sea Systems Command Contract No. N00024-89-C-3833, 10 December 1989 and 29 Sept 1993, respectively). The approaches that were used are an extension of the work introduced by Dr.Raymond to the National Academy of Sciences and published under NMAB 328, in 1976 entitled, "Rapid Inexpensive Tests for Determining Fracture Toughness". These methods were further developed for "Microstructural Analysis and Indexing of HY-130 Steel Weld Metals for SCC, for the High-Strength Steel Weldments" in support of the Subcritical Cracking Program, David W. Taylor Naval Ship Research and Development Center, DTNSRDC/SME-80/76, Sept '80. The accelerated test methods were then applied to "MP 159 Fastener Characterization Program using Accelerated Small Specimen Test Methods for (1) Stress Corrosion Initiation, (2) Crevice Corrosion, (3) Hydrogen Embrittlement, and (4) Fracture Toughness Testing of 1-1/4 Bar Stock and 1-1/4 Finished Bolts", (Final Report as Subcontractor to Standard Pressed Steel, Jenkintown, PA under contract to NASA, Huntsville, AL MSFC, 20 Aug 1993).

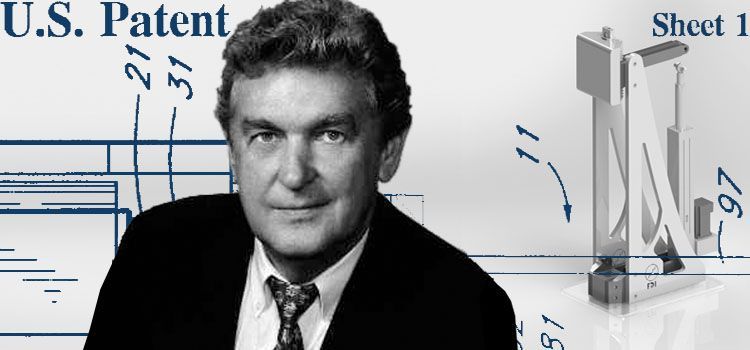

After completion of the Phase II (Naval Sea Systems Command Contract No.N00024-89-C-3833) the test method was commercialized in Phase III by creating FDI to manufacture the test machines. The 1991 SBIR resulted in three patents (Patent No. 5585570, 5505095 and 5549007). In addition, Dr. Raymond received the Los Angeles City Council of Engineers and Scientists George Washington, 1994 Engineer of the Year “for development of an innovative accelerated environmental test machine”, followed by a Phase I Navy SBIR Topic N99-199, Contract N00024-99-C4095 entitled, "Accelerated, Small Specimens Screening of High-Strength Corrosion Resistant Fastener Materials for Critical Naval Marine Applications". In 2006 after completion of the SBIR in 2000 he received the Industrial Fastener Institute Technology Award for “a significant contribution towards the understanding of hydrogen embrittlement, through years of research into accelerated methods for measuring the threshold stress, and development of the incremental step load technique as a practical means for qualifying and controlling hydrogen

embrittlement in fasteners.”

Since completing the Phase I award in 2000, LRA has worked to develop standards covering the Rising Step Load test method resulting in ASTM F1624 “Standard Test Method for Measurement of Hydrogen Embrittlement Threshold in Steel by the Incremental Step Loading Technique”. The test method has been inserted into ASTM F519 and NASM 1312/5. The test method has been adapted to testing fasteners resulting in it being incorporated into a ICC/AC193B standard for measuring the hydrogen embrittlement threshold stress of concrete anchor bolts. Recently, the latest standard that incorporate the RSL™ Testing Protocol is ASTM F2660 “Standard Test Method for Qualifying Coatings for Use on A490 Structural Bolts Relative to Environmental Hydrogen Embrittlement” has been released.